Smoke Seals

Smoke seals are required and “shall be in continuous contact with the mating element, and located so as to minimise interruption by hardware” (C6.1.2c).

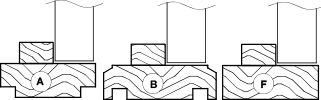

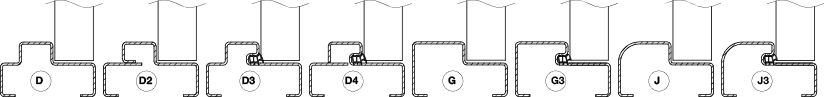

Pacific Smoke Control doors utilise frame-mounted rubber seals or else brush seals fitted to the door leaf.

Sill seals are not required in the Acceptable Solutions, but can be supplied fitted to the doors, typically as automatic drop seals.

Smoke Control Door Construction

As described in Appendix C, C6.1.2, smoke control doors have these characteristics:

- Constructed with solid core leaves with leaf thickness of minimum 35mm.

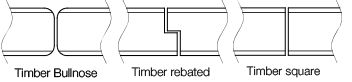

- If in timber frame, minimum 30mm thick timber

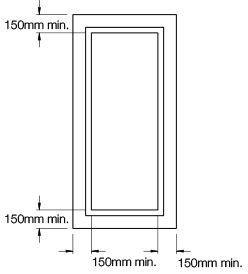

- Vision panel cutouts no less than 150mm from the leaf edges

- Maximum average clearances are:

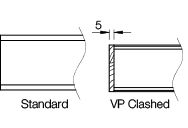

- Leaf to frame 3mm

- Leaf to leaf 5mm

- Leaf to top of any floor covering 10mm

- Additional facings are adhesive fixed

Self-Closing

All smoke control door leaves must be self-closing (Appendix C C6.1.4) and the self-closing device needs to be adjustable to meet the frictional forces requirements. A self-closer mechanism which activates in the event of a fire but does not operate at other times is acceptable (C6.1.5).

In C/AS2 (Risk Group SI) 4.6.5, smoke control doors in smoke separations subdividing a group sleeping area firecell need not be fitted with self-closers.

Latching

Latching of Smoke Control doors is not specifically required by the NZBC Acceptable Solutions, however positive latching may be required to provide adequate sealing against smoke. If present, the type of latching or other hardware used must not interfere with the ability of the door to self-close.

Frictional Forces

Requirements for the maximum forces required to open any smoke control door on an escape route are set out in Appendix C6.1.3.